Ball Mill RETSCH powerful grinding and .

A ball mill can grind and homogenize small sample volumes down to the nano range. The Emax is an entirely new type of ball mill for high energy input.

WhatsApp)

WhatsApp)

A ball mill can grind and homogenize small sample volumes down to the nano range. The Emax is an entirely new type of ball mill for high energy input.

Machinery and Equipment buys and sell Used Ball Mills for mining and ... Allis Chalmers Svedala ball mill, ... with approx 65 gallon working capacity, batch type mill.

In Grinding, selecting (calculate) the correct or optimum ball size that allows for the best and optimum/ideal or target grind size to be achieved by your ball mill ...

We are one of the prominent manufacturers and suppliers of Cement Ball Mill for Construction. The offered cement ball mill is widely used for grinding the

Advantages of Ball Milling. ... Because all of the solids in a ball mill are forced to endure thousands of impacts by the grinding media over several hours, ...

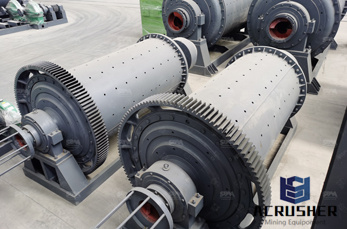

Ball Mill Working principle: When the ball mill works, motor and speed reducer transmit torque force to big and small gears of ball mill, so the barrel rotat...

Ball Mill Grinding,Manufacturers,Ball Mill Price,Working... Ball Mill Grinder Manufacturers SBM. Ball Mill Grinding is typically mill grinding plant used for small ...

cement ball mill working fundamentals. Gulin machine in Cement raw materials processing plant. How to Improve Ball Mill Working Efficiency Research ...

Autogenous and Semiautogenous mills. ... a rod mill, and some or all of the work done by a ball mill. All because of the range of mill sizes available, ...

Professionals should be proficient in their maintenance skills when working on these ... Ball mill technology is one of the most commonly preferred ... FAB 3R. All ...

3D Animation Demo working site of Ball Mill YouTube. Nov 12, 2014 ... 3D Animation Demo working site of Ball Mill .... Working principle of Ball Mill /ball ...

What Is Ball Mill And Its Working Principle? The usage of ball mill and its technical data Ball mill is widely used for grinding ores and rocks in metal and nonmetal ...

Grinding in Ball Mills: Modeling and Process Control ... The mill is driven by a girth gear bolted to ... The design of a ball mill can vary significantly ...

Jun 19, 2015· https:// Learn about Ball Mill Critical Speed and its effect on inner charge movements. The effect of Ball Mill .

Both the ball and pebble mills utilize a ... Metso ball/pebble mills ensure the technology is working hard ... Ball/pebble mills grind ores and other materials ...

See this useful summary Table of Bond Work Index by Minerals. For any circuit, whether a crushing circuit, a rod mill, or a closed ball mill circuit, the Work Index ...

Technical Note Why is the Bond Ball Mill Grindability Test ... Although the Bond Ball Mill Grindability Test has existed for more than 40 years, there is

W is the work index measured in a laboratory ball mill (kilowatthours per metric or short ton) P 80 is the mill circuit product size in micrometers;

Ball Mills Manufacturer Ball Mill Working Principle. A ball mill is a type of grinding mill, it is an aggregate for grinding and crushing (grinder) of hard materials ...

Ball Mill Working, Wholesale Various High Quality Ball Mill Working Products from Global Ball Mill Working Suppliers and Ball Mill Working Factory,Importer,Exporter ...

Cement Ball Mill Working Principle: Material enters spirally and evenly the first warehouse of the milling machine along the input material hollow axis by input ...

Ball Mill is a milling machine that consists of a hallow cylinder containing balls... The large balls tend to break down the coarse feed mater...Used for...

Make a Ball Mill in 5 Minutes ... Wiki says "A ball mill is a type of grinder used to grind materials into extremely fine powder ... seems to work pretty well ...

Ball mill Wikipedia, the free encyclopedia. A ball mill is a type of grinder used to grind materials into extremely fine powder for use in mineral dressing ...

WhatsApp)

WhatsApp)