The Most Efficient Way of Improving .

The Most Efficient Way of Improving Grinding Efficiency of Ball Mill. ... ratio of grinding balls to materials, grinding density and feeding granularity.

WhatsApp)

WhatsApp)

The Most Efficient Way of Improving Grinding Efficiency of Ball Mill. ... ratio of grinding balls to materials, grinding density and feeding granularity.

efficiency of sand mill. efficiency of sand mill XSM excellent mining crushing machinery products or production line design, the company is committed to building the ...

ball mill steel balls,US 600 1,200 / Metric Ton, Shandong, China (Mainland), steel ball, from Jinan Jinchi Steel Ball Co., Ltd. on

1. Introduction. Ball mills are the most common and versatile type of tumbling mill. They are remarkable in that they can operate over a very wide range of conditions ...

Maximize your grinding efficiency Grinding media solutions Steel grinding rods and balls. 2 ... Metso helps you improve mill availability and grinding efficiency.

Keywords: Milling; Efficiency; Balls; Size; Operation; Performance; ... significant role in the improvement and optimization of the efficiency of the mill [4].

Grinding Efficiency Ball Mill, Wholesale Various High Quality Grinding Efficiency Ball Mill Products from Global Grinding Efficiency Ball Mill Suppliers and Grinding ...

grinding aid mill process calculation how to calculate ball mill efficiency how to calculate cement grinding mill balls ball mill grinding media ...

High efficiency ball mill price for ceramic and stones,US 1,000 50,000 / Set, New, Ball Mill, depends on the from Zhengzhou Yufeng Heavy Machinery Co ...

ball mill efficiency formula. ... The efficiency of ball mill and ball mill is not only the level of the model, ... stone balls is better to » Learn More.

The quality of steel balls has a direct influence on both the productivity of ball mill, also affects the ball high and low consumption, which affect the cost of ...

Established in 1999, in addition to professional manufacturering of grinding steel balls, ... high wear resistance and high combined efficiency of grinding mill. ...

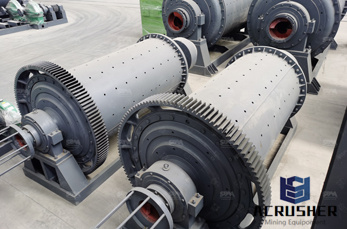

A Ball Mill grinds material by rotating a cylinder with steel grinding balls, ... efficiency with ball mills, ... any ball mill. Most ball mills operate most ...

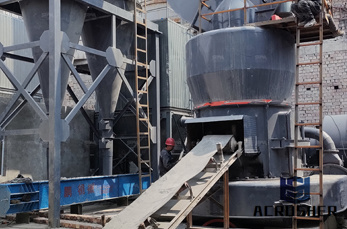

Ball mill is the key equipment for grinding after the crushing process, which is widely used in the manufacture industries, such as cement, silicate, new building ...

Ball Grinding Efficiency ... Effect of ball size and powder loading on the milling efficiency of a . 4 May 2013 of the smaller balls ... Find ball mill efficiency ...

efficiency of ball mill. ... aluminaball provides alumina balls, alumina grinding ball, mill linings alumina brick inert alumina ball, China Origin.

Influence of lifter height on the grinding efficiency of ball mill ... balls arrive at the exposed lifter directly instead

Ball Mill Grinder,as hammer crusher or cone crusher,is mainly used to grind materials in mineral, ... Steel balls or other grinding media in the barrel are lifted to a certain ...

Diaphragms, mill shell linings and grinding balls. The efficiency of ball mills can be significantly increased by the quality of your components.

for Accident Prevention Design for Energy Efficiency ... What is ball milling? A ball mill is a type of grinder used ... Temperature Size and Number of the balls

The optimal ball diameter in a mill 331 In accordance with Eq. 2, the necessary condition for grain comminution is:

high efficiency mining ball mill. ... High quality steel grinding balls for . Energosteel company is one of the leading grinding media manufacturers in Ukraine.

· Contact Us For Help: 2012 High Efficiency Cement Ball Mill Grinding Media, Buy 2012 High Efficiency Cement Ball ...

The new high efficiency and energy saving gas furnace. ... High production efficiency, ... Forged Grinding Balls | Grinding Cylpebs ...

WhatsApp)

WhatsApp)